IN-LINE CLEANING UNITS

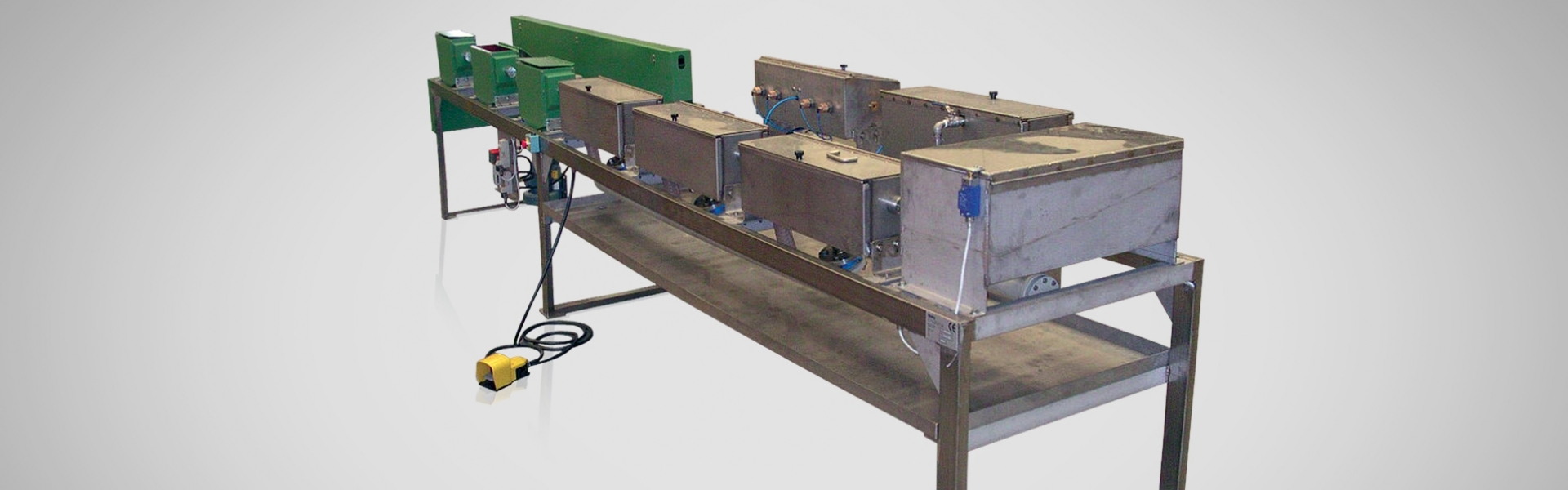

This unit is designed to clean the wire when it exits the dry wire drawing process, specially used in the stainless steel wire production.

It is installed at the exit side of the wire drawing machine, upstream from the wire collection station (spool/coil winding), and it is composed of various modular stages that can be positioned in a straight line or “U” shape, depending on the available space. The number of modular stages is defined according to the maximum required treatment speed and the quality of the cleaning process.

It is installed at the exit side of the wire drawing machine, upstream from the wire collection station (spool/coil winding), and it is composed of various modular stages that can be positioned in a straight line or “U” shape, depending on the available space. The number of modular stages is defined according to the maximum required treatment speed and the quality of the cleaning process.

Main Features:

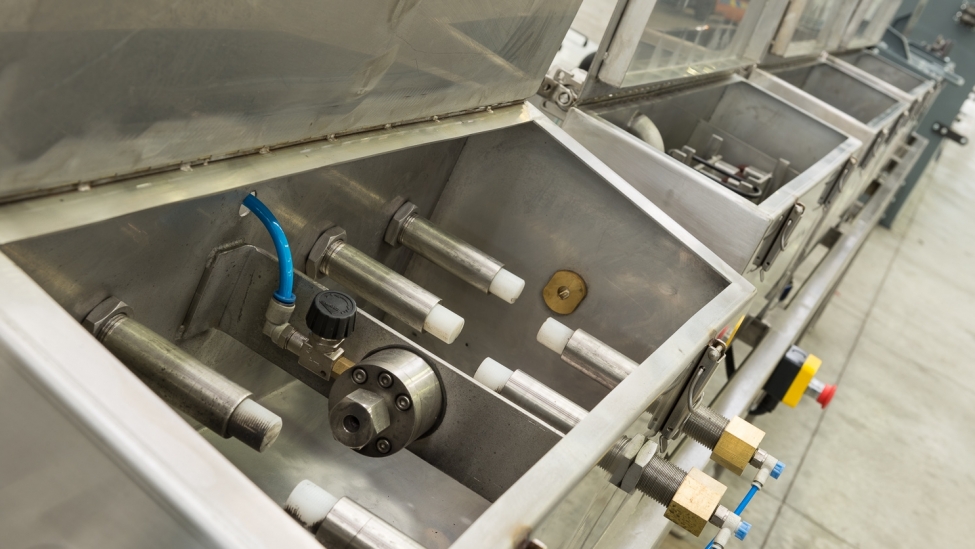

- Motorized helical brushing;

- Surface washing by abrasive pads in a hot water detergent mixture (3 stages with two tanks with heating elements and recirculation pumps);

- Possible wire deflecting unit for “U” turn of the line (for reversing process direction);

- Air wipes drying (2 stages);

- Hot air drying tunnel in countercurrent direction (2 air blowers).

| ULM Series | ||

|---|---|---|

| WIRE Ø | [mm] | 0.80 ÷ 1.60 |

| MAX. RESIDUAL | [g/m²] | 0.30 |

| MIN. WIRE Ø OUTPUT | [mm] | 0.10 |

| MATERIAL TO CLEAN | [-] | dry drawn stainless steel |

| MAX. SPEED | [m/s] | 20 |