BVM

CONTINUOUS TWIST

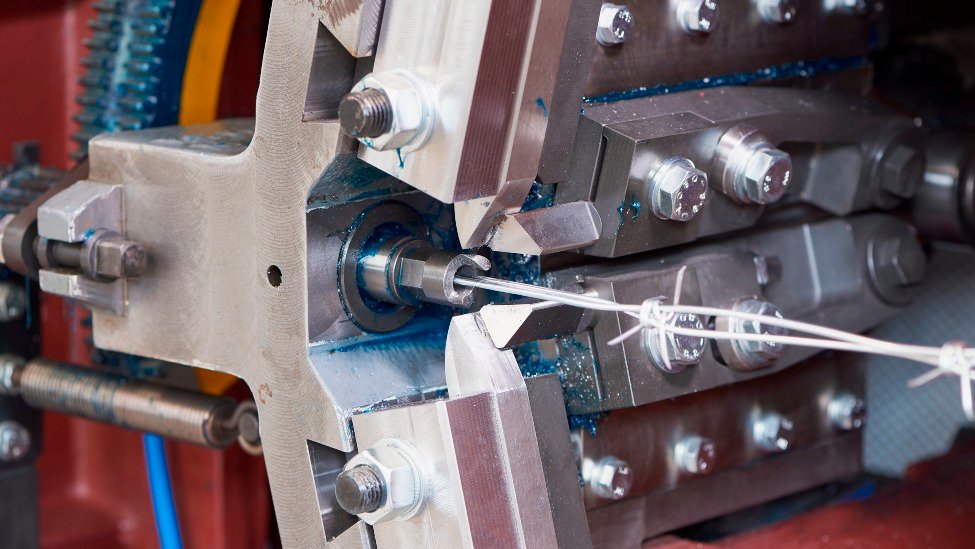

The BVM machine model is a fast processing machine catering for galvanized barbed wire that covers all the conventional barbed wire manufacturing typologies:

- Domingo

- Glidden

- Iowa

- Simplex

- Waukegan

The barbed wire is produced in a loop form due to the line wires being processed in clock-wise mode.

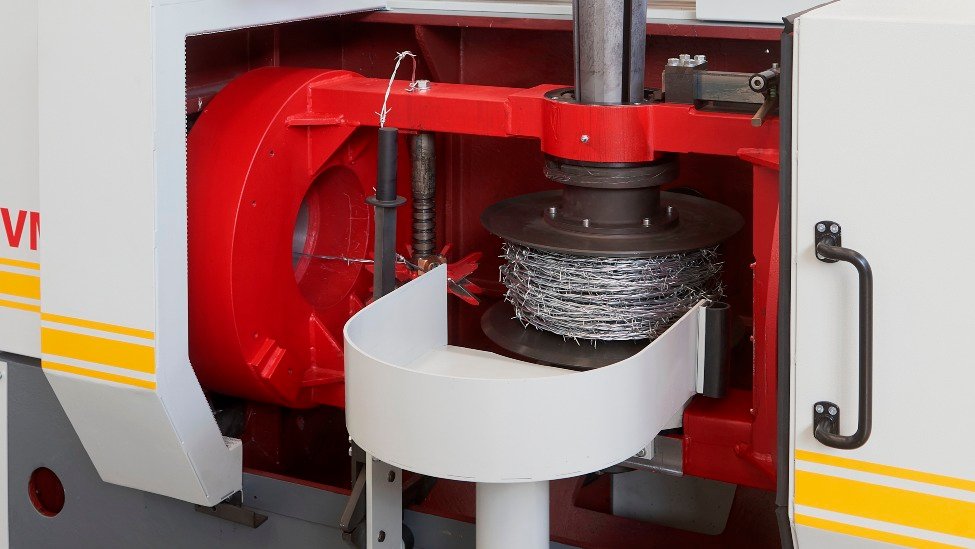

The machine is single motor-driven, equipped with a four-speed gearbox in oil bath. The machine is vertical and hence enables very easy access during normal set-up and maintenance operations. The winding spool is perfectly balanced and equipped with a semi-automatic unloading system that incorporates a swivel container in which the finished spool of barbed wire is dropped into once completed. This allows for a very quick spool changeover. Most types of spools can be used on this machine including wooden spools. Each spool can weigh up to a max. 35 kg (75 lbs).

Main Features

- Maximum fl exibility on confi guration of fi nal product;

- Selection of parameters by means of touch panel;

- Versatile machine due to independent parameters set up (distance between the barbs, quantity of barbs, torsions);

- Possibility to save receipts of different barbed wires parameters;

- Safe and easy handling of fi nished barbed wire coils;

- High machine effi ciency due to regenerative motors.

| Barbed Wire BV Series | BVM | |

|---|---|---|

| STRAND WIRE Ø INPUT | [mm] | 1.6 ÷ 2.8 |

| BARB WIRE Ø INPUT | [mm] | 1.6 ÷ 2.5 |

| PITCH | [mm] | 60 ÷ 150 |

| TORSIONS | [-] | 1.4 ÷ 4.0 |

| MAX. SPEED (*) | [m/min] | 50 |

| MAX. TORSIONS | [rpm] | 700 |

(*) Pitch in Inches: 3" ÷ 6"